Glycol Refrigeration System Design

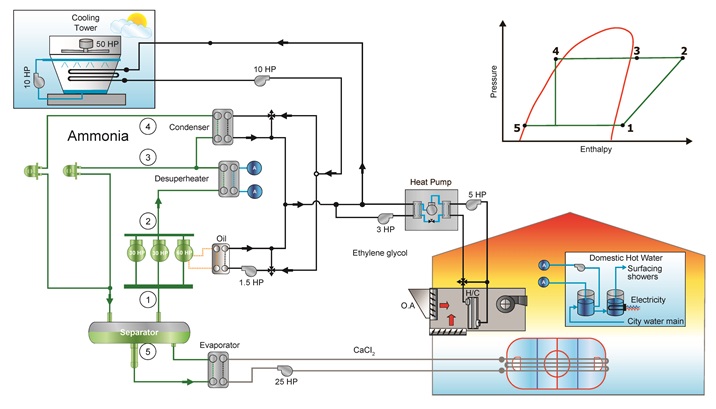

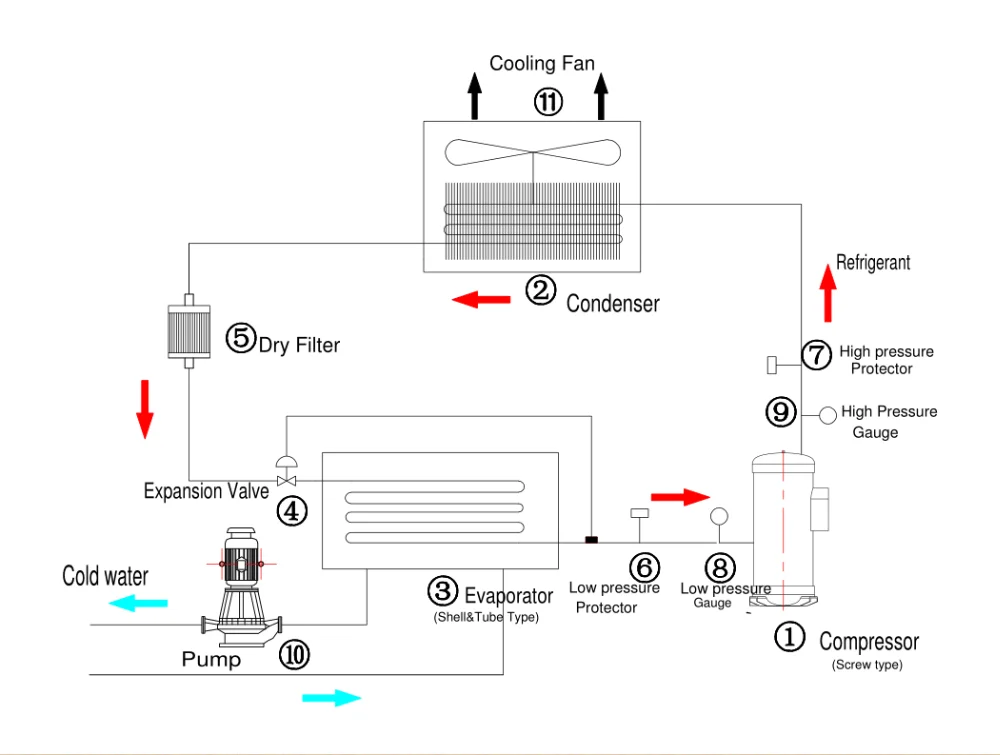

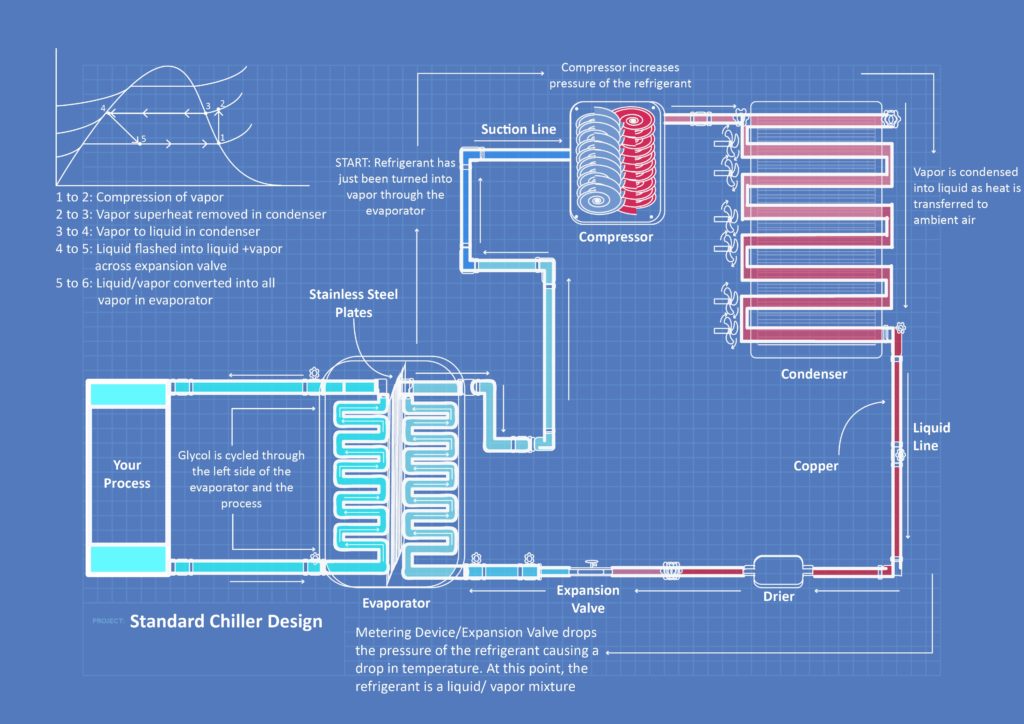

Glycol refrigeration system design. A chiller is a type of refrigeration system that cools a tub of glycol to reduce its temperature. The first step in setting up a glycol cooling system is to establish a glycol chiller in a closed loop system. Glycol systems perform best in medium temperature applications and are competitively priced versus CO2 systems.

Glycol refrigeration system is a refrigeration system using glycol as refrigerant carrier of water cooler. We have a dedicated team of technicians with the technical expertise and licenses to work with all types of refrigerants including ammonia and glycol refrigeration systems. Pure water freezes at 0 degrees Celsius 32 F and pure ethylene glycol freezes at -129 C 89 F.

With almost 50 years experience in the refrigeration business we have expert knowledge about all types of cooling systems and can create exactly what you need. GF Coolfit Pre-Insulated PVC80 welded stainless steel copper tubing etc. Propylene glycol will erode the pipe and could also cause bacteria problems.

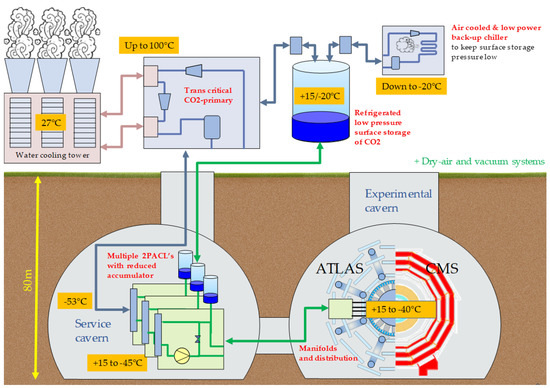

Glycol refrigerant systems from Hillphoenix. Refrigeration Swing Compressor capable of covering largest duty Circuit 4 Propylene Glycol 0C 1000 kWr COP 41 kWe 244 Compressor 1 Refrigerant Condenser 1 Buffer Tank Separator 3 Separator 2 Separator 1 Uni-tanks Fermentation 2100 kWR 14C Cooling Water Wort Cool stage 2 960 kWR 8C DAW 10C-1060 kWR Civils 3500kWR 8C CO2 Recovery 378kWR compression. If the ice is carrying the cook it will freeze so adding some anti-freezing liquid can avoid freezing and glycol can prevent freezing.

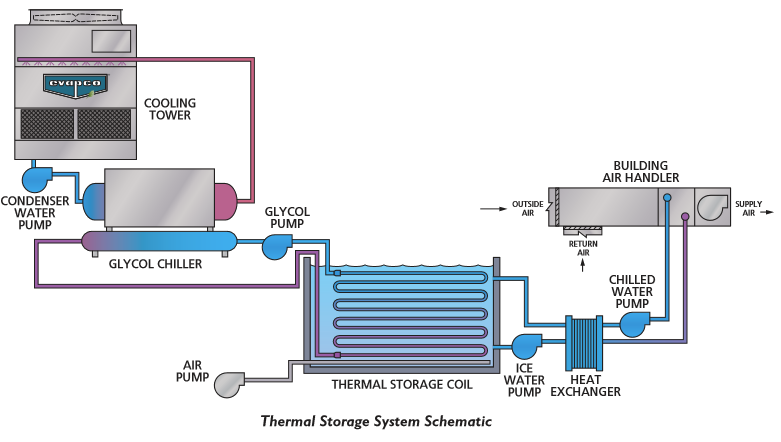

Glycol propylene glycol or propane-1 2-diol is widely used as heat-transfer fluid in commercial refrigeration applications and to reduce HFC refrigerant use in secondary refrigeration systems. Were always here to help. A glycol cooler is a process cooling system consisting of an insulated tank of glycol antifreeze solution with temperature control and refrigeration system.

November 12 2019 Seth McEldowney. This is why glycol cooling systems are becoming more common than ever before. Stage 1 of the system is a direct expansion system which chills the liquid glycol utilised in stage 2 of the process.

We design and install new commercial and industrial refrigeration provide existing plant refurbishments retrofits upgrades as well as offer a cool room design and installation service. Check all chilled cooling application process piping for leaks prior to adding glycol solution.

November 12 2019 Seth McEldowney.

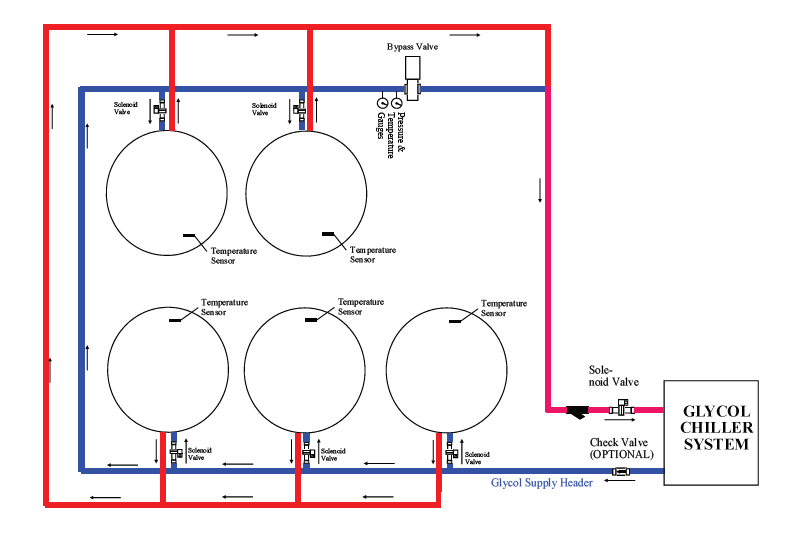

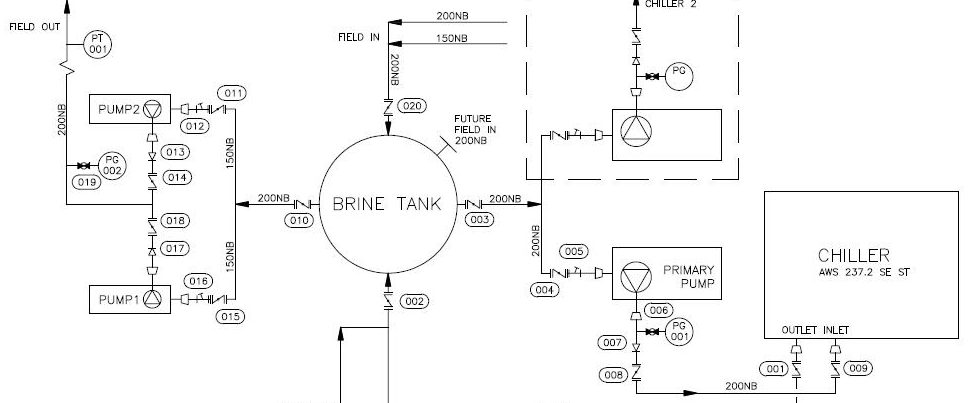

Check all chilled cooling application process piping for leaks prior to adding glycol solution. A glycol refrigeration system is made up of 2 sub-systems often referred to as a secondary loop system. Water foods has wide experience in the design and installation of Cold Store cooling employing a glycol Secondary Refrigerant Systems Glycol or secondary regfrigerant systems for cold rooms or cold stores feature an outdoor glycol chiller interconnected to the indoor blast coolers with mild or stainless steel pipework through which low temperature food safe glycol is circulated. These photos below are a visual aid that can help you locate these glycol chilling components on your GD refrigeration unit and also give you a quick reference to better service and maintain your glycol chilling system. Designed originally as a draught beer cooling system about twenty years ago the ecoCOOL Lancer glycol beer system has evolved into a holistic beer system that delivers the best quality product and that can cater for all your other refrigeration products big or small such as beer cold rooms food cold rooms bottle coolers or wine chilling equipment etc. If the ice is carrying the cook it will freeze so adding some anti-freezing liquid can avoid freezing and glycol can prevent freezing. Zero Zone glycol refrigeration systems are highly reliable and unlike other traditional coolants glycol increases temperature holding time for a more consistent temperature throughout the system. Check all chilled cooling application process piping for leaks prior to adding glycol solution. Proudly supported by GD Chillers Inc.

Water foods has wide experience in the design and installation of Cold Store cooling employing a glycol Secondary Refrigerant Systems Glycol or secondary regfrigerant systems for cold rooms or cold stores feature an outdoor glycol chiller interconnected to the indoor blast coolers with mild or stainless steel pipework through which low temperature food safe glycol is circulated. Energy Savings Our systems are simple to operate and typically use one-third less energy by incorporating loop design. The first step in setting up a glycol cooling system is to establish a glycol chiller in a closed loop system. Were always here to help. For over 30 years Serchill has worked with our clients to design build and service their Glycol and chilled water refrigeration systems. The entire refrigeration system of the g glycol chiller system design is a fully closed loop glycol cooling system There will be no oil mist at high temperatures Does not absorb moisture in the air at low temperatures. A chiller is a type of refrigeration system that cools a tub of glycol to reduce its temperature.

Post a Comment for "Glycol Refrigeration System Design"